As technology advances, we realize that we can use automation, robots, and machines to do the hard jobs, while we use our human crew to find better solutions, do creative tasks, and focus on more demanding projects. Many companies are starting to implement robots on their working sites, and if you are wondering why that is, here you can read about the different ways the machines can improve the overall safety of the employees and workers.

1. Lifting heavy objects

One of the main types of injuries that happen on sites is back and spine injuries. Workers say that after working physical labor for several years they suffer from chronic pain, and they have to either spend thousands of dollars in therapy, or they have to learn how to live with the pain. If the crew has young adults that are in their early 20s, lifting weight and heavy objects constantly can cause even more serious damage and it can lead to disability.

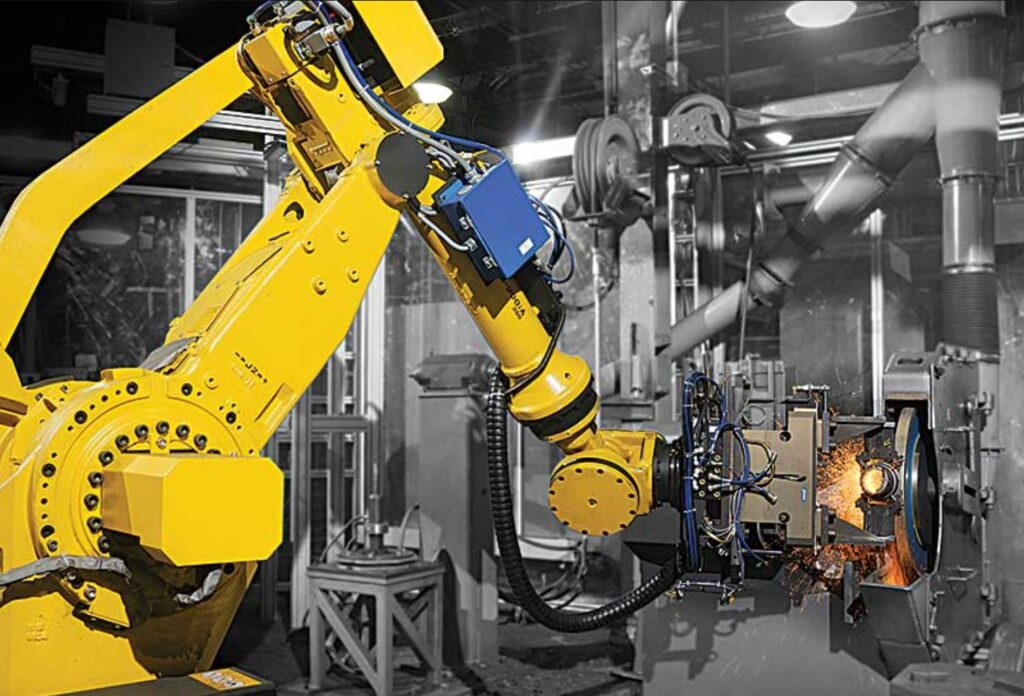

When we incorporate robots and machines in the worksite, the human crew will be protected. The machines can lift a lot of weight without an issue, and they won’t get hurt. The worst thing that can happen is the machine breaking, and as long as you follow the rules and as long as you never load the machine with heavier things that it can carry, everything will be okay.

With this, you will be protecting your employees and they can focus on more creative things, or just move light objects around.

2. Working at heights

Companies spend thousands of dollars on safety equipment for their crew when they have to work at heights. Unfortunately, despite all of the measures that are taken, people can still get hurt and fall of the equipment or the building.

The number one priority is to keep the workers safe, and using robots when things need to be done will improve the overall site safety. The machines can reach objects that are a lot higher, and this will protect the human crew. They can also be installed on construction sites and they can be programmed to finish a task without getting close to the edge.

It is said that when it comes to aerial lift equipment, machines can either reduce the need for human workers, or they can fully replace them. This means that your employees will never again have to climb on the roof or hang on the side of a skyscraper. With the machines, the risk of falls from heights will be significantly reduced.

3. Cuts and bruises

Sometimes things are too difficult to install, or the workers have to install sharp and easily breakable objects on the site. If only one thing goes wrong, it can lead to serious safety risks and injuries.

When the conditions are slippery or too hard to reach, it is better to rely on the machines to get the job done. This company produces glass manipulators that can replace the crew and help out a lot when it comes to working with glass and lifting heavy objects. No matter if your business is about construction, window fabrication, or building and construction, it is always better to use robots if you want to make sure your workers are safe.

When we rely on machines to install things in narrow spaces or hard to reach places, we lower the risk of cuts, bruises, and serious injuries that people face.

4. Sunburns and fatigue

When a building is getting built, there are no trees around, and in the earliest stages, there is no roof to hide under when the weather is too hot. Workers have to wear a lot of safety equipment and that can lead to them dehydrating, fainting, or, if they are not following all the safety protocols, get sunburned.

All of these things can lead to your crew ending up in the hospital, and in case they faint while working at heights, it can lead to serious injuries. If the employees don’t take a lot of breaks and if they don’t drink enough water, they risk getting hurt, or they can just make a mistake that can jeopardize the whole project.

A machine can work anywhere, in any condition and it won’t need a break. No matter if it is freezing cold, or if it is burning hot outside, chances are, the robot won’t have any issues finishing the task. It will not need to stop working and rest, and it won’t get damaged if you leave it in the sun for too long.

5. Time and efficiency

Everyone has a deadline, but there is a huge difference between trying to speed things up when you are working an office job and trying to work faster when you are constructing a building.

When something needs to get done really fast, the workers tend to ignore the safety regulations and they rush things without thinking about the steps they take. This means that they can slip, fall down, cut themselves or try and lift a really heavy object. This will lead to serious injuries and the work will not get done on time.

So, if you want to be on time, always finish before the deadline and if you want everything to be done correctly while keeping your team safe, you should look into introducing machines in your work process and building site.

The statistic shows that robots can get the job done three to five times faster than people and when they are programmed and used correctly, there won’t be any mistakes or errors.

All of these things don’t mean that the human crew should be replaced by machines and that people should lose their jobs. When we start using people for their skills, creativity, and knowledge, we will be able to take the company to the next level. Machines cannot think and they cannot hurt themselves. It is always better to keep the people safe and give them higher responsibility tasks, and to use the robots to the maximum when it comes to heavy lifting, working at heights, and insecure places.